Cornhole Board Preparation:

Begin with a smooth, dry dust free board. Fill any large divots and sand smooth. We suggest painting or sealing your boards to prevent moisture absorption and warping. Use a smooth foam roller for the top to create a smooth finish. If using a varnish or sealer we suggest using water based instead of oil based. It's much easier to clean up and does not yellow over time. When painting, an outdoor semigloss gives the best durability and adhesion. Let your boards cure for a minimum of 48 hours before applying the wrap. Inspect the surface for any imperfections and smooth as necessary. Never use any type of wet application. The 3m wrap film is designed to be installed dry and has a built-in air-egress technology to release air for an easy bubble free application.

You will need the following materials in order to install your cornhole wrap:

- Squeegee

- Masking or painter’s tape

- Utility knife or scissors

- Water-based polyurethane

- Paint brush or roller

Cornhole Wrap Instructions:

STEP 1: Unroll your cornhole wraps from their shipping container and lay on a flat surface.

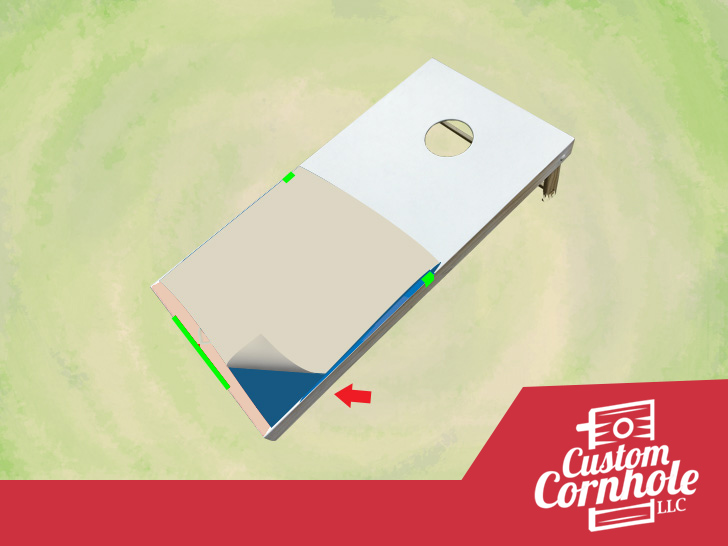

STEP 2: Using masking tape, carefully tape down the bottom and sides of the decal to the cornhole board, as shown.

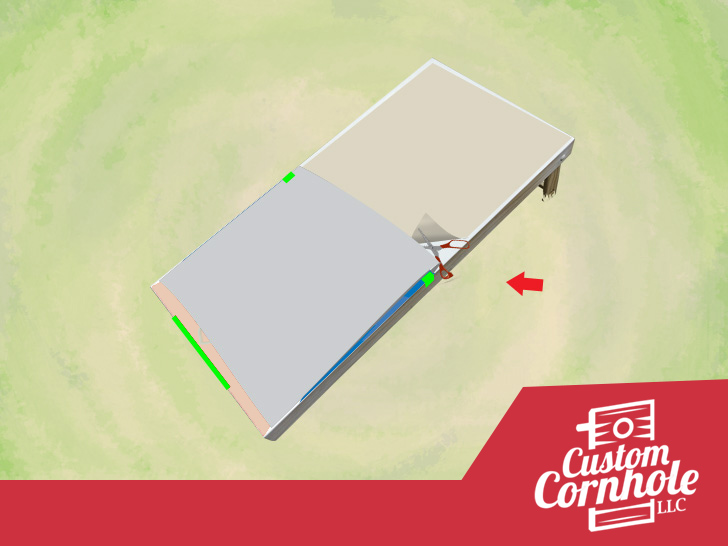

STEP 3: Pull down the top section, above the tape and carefully remove the backing paper to expose the sticky side.

STEP 4: Using scissors, or your utility knife, remove the entire top section of the backing paper.

STEP 5: Starting just above the tape, where you removed the backing paper, gently press the sticky side down to the cornhole board. Use your squeegee to remove any air bubbles as you work your way up.

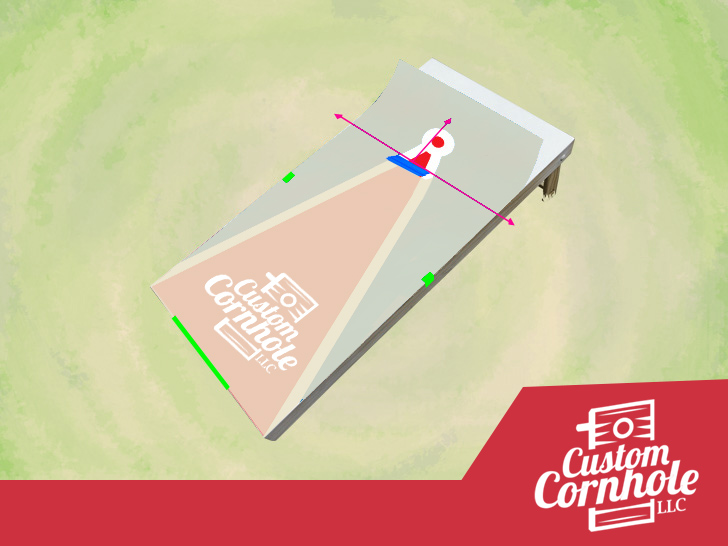

STEP 6: After removing all air from underneath the wrap, gently peel away masking on top of the graphic so that the graphic does not lose adhesion to the board. Use your utility knife to carefully cut out the hole.

STEP 7: Remove the tape and fold back the bottom of the decal. Carefully remove the paper from the bottom and squeegee your way from the middle of the board to the bottom.

STEP 8: Using your paint brush or roller, cover the entire board/decal with water-based polyurethane.

STEP 9: Repeat this process on your other board.

Video:

Cornhole Board Care:

Store your boards in a clean dry place indoors when not in use. Never leave them outside. Long term exposure to weather can cause your boards to absorb moisture resulting in warping or wrap failure. If you have any questions or issues with installation or caring for your boards please contact us right away.